So I have been working on the fitting the canopy frame, the first step on the canopy tasks. I had taken a month off to do yard work and whatever else I could find to avoid the canopy stuff. Finally I decided it needed to get done while the weather was warm.

The canopy frame was fairly close to perfect from the factory. I had to tweak 6 spots in the front hoop. I have a little more to go in the back hoop. But the back hoop requires less force and is already really close.

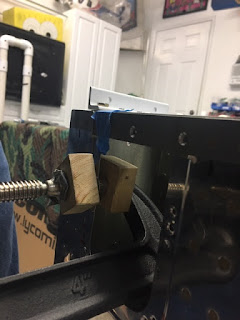

I took the advice of others and will cut the

canopy front tubes, and will put the canopy track on, after the frame is

bent. I

found it was much easier to do this without the tracks being on; I just

used a wood space under the front tubes to raise the canopy frame up to

about the right spot.

Here is how I bent the front hoop use a 3/4" conduit bender from the precision tool isle at Lowe's:

I then measured the height of the gap to make sure each side was even. I found I had to take out a slight bend on one side to make it even.

Here is the overall fit of the frame. The top height is not correct because the frame has not been sized for the track rollers.

Like everything else on this build, I stressed over this, but once I got into it, it wasn't so bad. Just keep swimming- Dora

Sunday, June 28, 2020

Wednesday, May 20, 2020

Finishing Kit -Part 1 of 100

So it is time to start the finishing kit. First up is the canopy. it seems nothing has caused more trepidation from those who have gone before.

So I dive in.

The roll bar is attached first using special spacers. These have to be drilled to match the holes in the canopy rails. I drilled a pilot hole first, then flipped the spacers over and drilled the final hole from the "backside". I did this to avoid the drill bit wondering due to the "split level" front side.

The rest of the roll bar install went per plans. I did have to use a 0.025" shim under the left side to get a good fit, as mentioned in the plans.

I started fitting the canopy slider tracks too. I am installing the Supertracks from Flyboys that allow the canopy to open up farther. I order the longer RV 8 track spacer to avoid a split in the track. The trouble I ran into is bending the curve. Turns out using a simple wood block and the Armstrong method, I was able to bend it to match the full size template, no problem.

Drawing the center line on the spine spacer was a bit tricky, but I found I could use a carpenters level to draw a line holding the square against one side, then draw another line holding the square against the other side of the piece. This produces two lines on the part, with the exact center being between the two lines. In the picture below you can see the longer spine spacer,and looking closely, you can see the double line markings.

Things are slowing down now that the beach is open. But I can't let summer get in the way (too much) so I am determined to keep on making progress everyday.

So I dive in.

The roll bar is attached first using special spacers. These have to be drilled to match the holes in the canopy rails. I drilled a pilot hole first, then flipped the spacers over and drilled the final hole from the "backside". I did this to avoid the drill bit wondering due to the "split level" front side.

The rest of the roll bar install went per plans. I did have to use a 0.025" shim under the left side to get a good fit, as mentioned in the plans.

I started fitting the canopy slider tracks too. I am installing the Supertracks from Flyboys that allow the canopy to open up farther. I order the longer RV 8 track spacer to avoid a split in the track. The trouble I ran into is bending the curve. Turns out using a simple wood block and the Armstrong method, I was able to bend it to match the full size template, no problem.

Drawing the center line on the spine spacer was a bit tricky, but I found I could use a carpenters level to draw a line holding the square against one side, then draw another line holding the square against the other side of the piece. This produces two lines on the part, with the exact center being between the two lines. In the picture below you can see the longer spine spacer,and looking closely, you can see the double line markings.

Things are slowing down now that the beach is open. But I can't let summer get in the way (too much) so I am determined to keep on making progress everyday.

Friday, April 24, 2020

Calling it- fuselage done

Well, the last lines of the fuselage kit's instructions have been completed; I am calling the fuselage kit done. It doesn't look like much progress, but a ton of work and learning.

I added a doubler for the ELT antenna. It sounds simple, but took longer than expected. Everything else went OK. I had a really good bucking bar helper; I am not sure how anyone could do this alone.

It took me a little less than two years to complete the fuse. Seems for many others, the slow build fuse takes twice as long as the wings. It seems I am no exception to this rule.

I was able to attached the side braces on the bench before installing the turtle deck; I can't image doing this on the plane. Those elevator supports I built several years ago really came in handy.

Next up, the finishing kit, starting with the canopy.

I added a doubler for the ELT antenna. It sounds simple, but took longer than expected. Everything else went OK. I had a really good bucking bar helper; I am not sure how anyone could do this alone.

It took me a little less than two years to complete the fuse. Seems for many others, the slow build fuse takes twice as long as the wings. It seems I am no exception to this rule.

I was able to attached the side braces on the bench before installing the turtle deck; I can't image doing this on the plane. Those elevator supports I built several years ago really came in handy.

Next up, the finishing kit, starting with the canopy.

Saturday, March 28, 2020

Tail Wiring

So I am trying real hard to get the turtle deck on the tail. But first I decided I would install the wiring to the tail and the ELT mount; basically as much as I could before covering up the tail section. I really dread the thought of having to crawl in the tail to do systems installation.

So the pitch autopilot servo is in and wired, and the Canbus to the tail mounted GMU11 magnetometer is installed. I also installed a DTM connector in the tail for the electric elevator trim.

Lastly I installed the ELT mount kit from Vans. Of course there was a slight mod so that the mounting hole pattern would fit both of the most popular ELTs.

All that's left is the ELT wiring, and the doubler for the ELT antenna, then I think I can install the tail's top skin, or turtle deck.

So the pitch autopilot servo is in and wired, and the Canbus to the tail mounted GMU11 magnetometer is installed. I also installed a DTM connector in the tail for the electric elevator trim.

Lastly I installed the ELT mount kit from Vans. Of course there was a slight mod so that the mounting hole pattern would fit both of the most popular ELTs.

All that's left is the ELT wiring, and the doubler for the ELT antenna, then I think I can install the tail's top skin, or turtle deck.

Sunday, March 15, 2020

Subpanel Layout

So I am looking at subpanel layouts. My equipment not on the panel is all Garmin:

G3X displays (GDU 430)

GNX 375 GPS/ xpnder

GNC 255 Com1 / nav

GMA 245 Audio panel

GMC 507 Autopilot controller

G5 backup attitude

Behind the panel is:

GSU25 ADHARS

GMA245R (GTR20) Remote Radio

GEA24 Engine interface

GAD 29 ARNIC interface

GAD 27 Airframe Interface (flaps, etc)

Here is my layout.

Please provide comments on the layout, especially the pieces on the subpanel.

Thanks

G3X displays (GDU 430)

GNX 375 GPS/ xpnder

GNC 255 Com1 / nav

GMA 245 Audio panel

GMC 507 Autopilot controller

G5 backup attitude

Behind the panel is:

GSU25 ADHARS

GMA245R (GTR20) Remote Radio

GEA24 Engine interface

GAD 29 ARNIC interface

GAD 27 Airframe Interface (flaps, etc)

Here is my layout.

Please provide comments on the layout, especially the pieces on the subpanel.

Thanks

Friday, February 21, 2020

forward fuse

The forward fuselage of my slider is a little tricky.

There is a slight bend in the sub panel near the bottom; without this, the fit is terrible. I marked the bend, used an 18" brake on the outside, and a block of wood clamped to the table for the center section's bend.

.

The center web does not have prepunched holes in either the firewall, nor the web.

There are many ways others have installed this part. Here is what I did:

I first built up the web per the plans. Then I assembled it all together but put the forward skin on one hole back, so I can see to mark the location of the web on the firewall.

I made the holes in the same vertical location as the outside ribs

Then I put the skin on properly, drilled the top hole and clecoed.

I then removed the skin, aligned the rib to vertical, and drilled the remaining holes.

Unfortunately, the center brace is now no longer sitting on the firewall angle, so I will make a spacer. I had aligned the angle to the web based on a center line drawn on the angle. I probably should have drilled the rib to firewall first before drilling the angle to the web.

Friday, January 24, 2020

Quick Fuse update

So I have been working on the tail fairing now that the tail mechanical attach is done. I figured I would get it done before the tail comes off. The stock fairing fits really nice; much better than older posters have led me to believe. I used the cut lines, but these were too severe in the rear, so next time, I would leave a little extra there and trim, fit, trim, fit, etc. Nothing major for mounting, just takes time to find the underlying holes in the fuse. I measure the location of the holes in the fuse without the fairing; added the fairing, marked the hole locations on the fairing, then drilled a #50, then a 3/32 hole in the fairing, cleco'd and moved on to the next. Next I will enlarge the holes to #40, countersink the fiberglass for the #6 flathead screws, then enlarge the holes to #6, remove the fairing, and install the riv nuts.

After the tail fairing, I finished the inspection plates for the elevator. I did not dimple the holes for the nut plates when I built the fuse. My squeezer was too big to fit for all the holes. I had to get creative and use some blocks of wood to hold the dimple dies and a large c clamp.

Subscribe to:

Posts (Atom)