It has been awhile since I posted; its been a fun summer, not much building thou.

Brakes are in as shown below. Still have a question if I will stay with the plastic, or move towards the AN lines. I guess the first fill tests will determine if there are any leaks. I used the solid stainless rods for the brake pivots. The brakes are very nice with good return force. I have a set of helper springs which I do not plan on installing; the pivot rods worked out so well, I don't see a need for helpers.

I am now installing the tail. The horizontal stab is on. For drilling those AN3 bolts, one really needs a 6" long drill bit.

On the vertical fin, my 90 degree drill attachment died, so I am waiting for the new one to arrive. I could drill without it, but after the experience with the horizontal stab, I would rather wait for the tool to make it easy.

Like most things, I was worried about getting the tail on right. But by taking it slow, it all worked out.

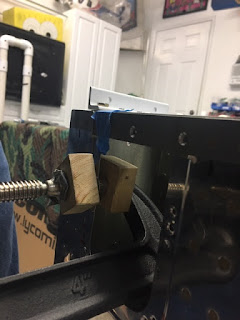

This picture shows much of the progress, tail on, engine in house, new upgraded motor mount, and sponge bob guarding it all.

I haven't decided if my next chapter will be the canopy or engine / electrical; it is pretty cold now, I might save the canopy for the warmer months.